In marine engineering, submarine cables are crucial links connecting offshore wind farms, oil and gas platforms, and communication systems. To ensure stable cable operation in complex marine environments, effective protective measures must be implemented. Bend stiffeners are a key component.

The function of bend stiffeners

Bend stiffeners are installed at the junction of submarine cables or umbilical cables with rigid structures (such as j-tubes, i-tubes, and platform interfaces). Their primary functions include:

• Limiting bend radius: Preventing excessive bending of the cable due to surges, tidal currents, and installation stresses.

• Reducing fatigue damage: Distributing stress concentration, extending the service life of the cable.

• Improving stability: Maintaining the safety of cable interfaces in dynamic environments.

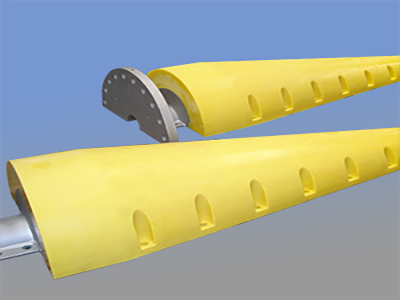

Advantages of split bend stiffeners

Conventional bend stiffeners are typically integral structures that must be installed before cable laying, resulting in complex installation. In contrast, split bend stiffeners offer distinct advantages:

• Easy installation: They can be installed directly after cable laying, reducing construction restrictions.

• Modular design: Composed of symmetrical components, they facilitate transportation, storage, and maintenance.

• High flexibility: Can be quickly customized based on cable diameter and application scenario.

• Reduced cost and construction time: Reduces pre-installation steps and improves project efficiency.

Installation locations on submarine cables

Split bend stiffeners are typically installed at:

• The interface between the submarine cable and the platform riser

• The transition point where the cable enters the J-tube or I-tube

• The connection point between the cable and the floating structure

Installing split bend stiffeners at these critical locations significantly improves the cable's bending resistance and reduces damage caused by waves, currents, and installation operations.

Submarine cable types

Split bend stiffeners are suitable for a variety of submarine cables, including:

• Submarine power cables: Used for power transmission in offshore wind power plants, island power supplies, and other applications.

• Fiber optic communication cables: Provide transoceanic communications and ocean monitoring data transmission.

• Umbilical cables: Used on oil and gas platforms to transmit power, hydraulic control, and signals.

• Flexible pipelines: Transport oil, gas, or chemicals.

Split polyurethane bend stiffeners

Due to their flexible installation and superior protective performance, split bend reinforcements have become a crucial component of submarine cable protection system. They not only improve construction efficiency but also ensure the long-term safety and reliable operation of offshore cables.