As the global energy transition accelerates, offshore wind power is venturing from shallow waters into the deep sea. Since traditional fixed-bottom foundations are unfeasible in deeper environments, Floating Offshore Wind (FOW) has become the industry-recognized future. However, the core lifeline supporting this vision—Dynamic Cables—is facing unprecedented mechanical and environmental challenges.

I. From Static to Dynamic: A Paradigm Shift in Cable Mechanics

In traditional fixed-bottom wind farms, cables are buried under the seabed or secured to the turbine tower, remaining relatively static. In a floating scenario, however, cables must survive the tripartite motions of waves, currents, and the floating platform itself.

Large-Amplitude Displacement: Floating platforms move across six degrees of freedom (surge, sway, heave, roll, pitch, and yaw). This requires cables to possess extreme flexibility, acting like an "umbilical cord" that sways with the platform.

High-Frequency Fatigue: Continuous wave cycles cause millions of bending movements. Without proper design, the copper or aluminum conductors inside the cable are highly susceptible to metal fatigue and fracture.

The Core Challenge: The focus of protection technology has shifted from simple "corrosion and abrasion resistance" to complex fatigue life management.

II. The Art of Buoyancy Modules and Lazy-Wave Configurations

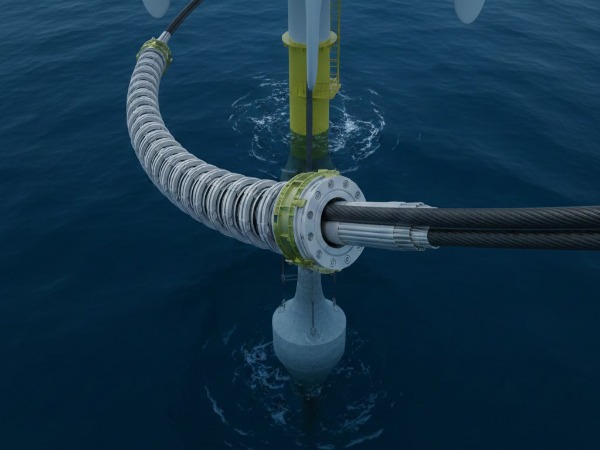

To mitigate the massive tension exerted on the cable's hang-off point by platform motion, engineers utilize Buoyancy Modules and configure the cable into specific shapes—the most classic being the Lazy-Wave layout.

1. The Critical Role of Buoyancy Modules

Tension Decoupling: By installing buoyancy modules at specific sections, the cable forms an upward arch in the water. This "wave" acts as a physical buffer, effectively absorbing the pull generated by platform movement and ensuring loads at the connection points remain within safe limits.

Touchdown Point (TDP) Protection: The Lazy-Wave structure reduces friction and impact at the point where the cable meets the seabed, extending its operational lifespan.

2. Essential Ancillary Hardware

Beyond buoyancy modules, Bending Restrictors and Bend Stiffeners are indispensable. Installed at the cable’s entry point to the platform, they prevent irreversible structural damage caused by over-bending.

III. The Green Revolution: Eco-Friendly Materials and Sustainable Sheathing

For policymakers and industry researchers, environmental compliance in deep-sea development is increasingly becoming a market entry standard. The evolution of Cable Protection Systems (CPS) is moving in two directions:

Recyclable Polymers: Traditional polyurethane (PU) or polyethylene (PE) layers are being replaced by more easily recyclable thermoplastic elastomers to enable closed-loop processing after wind farm decommissioning.

Biodegradability and Bio-friendliness: New coatings are being developed to inhibit marine growth (preventing additional weight/drag) while ensuring that no microplastics or toxic chemicals are released into the deep-sea environment over a 10-year lifespan.

Conclusion

Dynamic cables and their protection systems are the lifelines of deep-sea wind power. Only through the precision of mechanical design, the intelligence of buoyancy components, and the "greening" of materials can we truly achieve the grand ambition of harvesting energy from the deep blue.