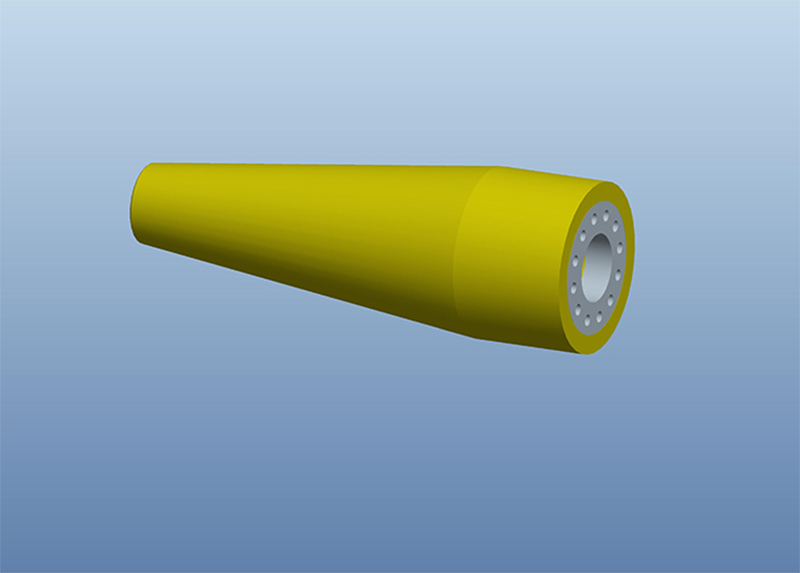

Polyurethane bending stiffener is a polymer structure Marine cable protection device, its specification model with the rigidity of 50A-70D, suitable for protecting 26/35/66/220KV submarine cable.

Hardness

50A–70D Polyurethane covers a broad hardness spectrum, ranging from soft, flexible elastomers to rigid, structural plastics. At the lower end (50A–90A), the material offers high elasticity and excellent flexibility, ideal for absorbing dynamic loads and preventing sharp cable bends. Moving into the D scale (50D–70D), polyurethane becomes progressively stiffer, delivering strong structural support, high abrasion resistance, and durability under heavy subsea loads. This wide hardness range allows bend stiffeners to be tailored precisely to the mechanical requirements of different cables, risers, and umbilicals, ensuring both protection and long-term reliability in offshore environments.

Features

• Lower weight

• Due to no steel, no cathodic protection

• Reduce acquisition costs

• Shorten assembly time

• Precise positioning and separation of individual hoses

• Weaken documentation required due to no steel

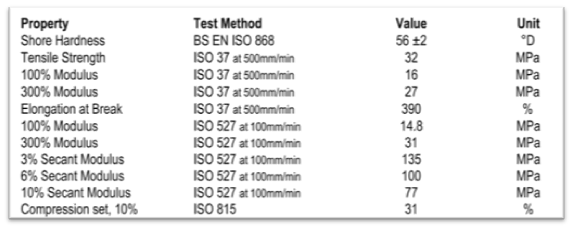

Raw Material Characteristics

The use of Dow Chemical Marine engineering HYPERLAST series of polyurethane materials, with excellent fatigue resistance and mechanical properties.

Application

The bending stiffener is mainly used in the connection of submarine cable, sea pipe and rigid equipment, where the submarine cable is prone to dynamic fatigue and bending. After the rigid connection point is installed, the bending stiffness of the cable/pipe can be improved, and the bending resistance and fatigue resistance can be improved. Therefore, the bending reinforcement is especially suitable for the rigid node protection of dynamic cable/pipe.

If you have more questions about bending stiffeners, feel free to contact Philson and we will answer them for you.