Riser J-tube Centralizer

In the field of offshore oil and gas, offshore wind power, the J-tube centralizer plays a vital role in guiding and protecting the riser or submarine cable from the seabed structure to the offshore platform through the J-tube. It ensures that the pipe and cable remain centered inside the J-tube, preventing mechanical damage caused by friction, vibration, or deviation. This effectively improves the installation efficiency and operational safety of the system, making it a key component in ensuring the stability of the deep-sea energy transmission system.

Role of J-tube centralizers in risers

A J-tube centralizer is a protective and guiding component installed around a riser or subsea cable. Its main functions include:

• Central alignment: Ensures that the riser or cable remains centered within the J-tube during installation and operation, preventing contact with the inner tube wall.

• Friction and impact reduction: Minimizes mechanical wear and potential damage caused by movement, abrasion, or vibration within the J-tube.

• Stress distribution: Helps evenly distribute loads along the riser, reducing localized stress points that can lead to fatigue or failure.

• Facilitating smooth pull-through: Aids in cable or riser installation by ensuring low-drag, smooth movement through the J-tube bend and transitions.

These benefits are especially crucial in deepwater environments where structural fatigue and equipment longevity are major concerns.

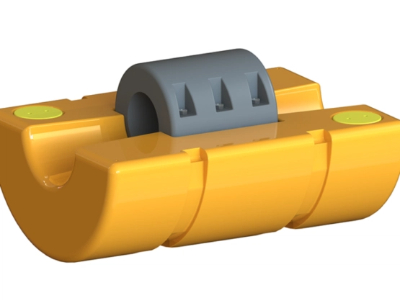

Symmetrical (Haval) design

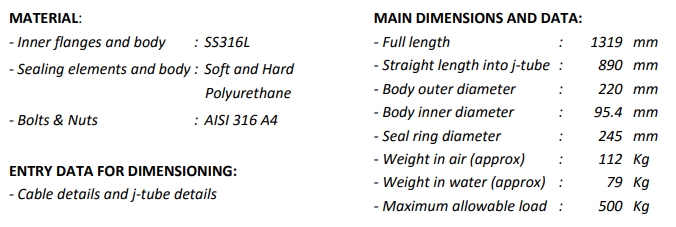

• Entry part: Conical head design, supported by polyurethane.

• Fixed part: Made of 316L stainless steel, corrosion-resistant and sturdy.

• Polyurethane seal: The center clamp of the riser is fixed by a polyurethane seal on the outside.

At regular intervals inside the straight portion of the J-tube: To maintain centering and avoid long unsupported spans that may lead to buckling or vibration.

The number and spacing of centralizers depend on factors such as riser diameter, material, water depth, and J-tube curvature.

Usage scenarios

J-tube centralizers are widely used across multiple offshore pipeline and cable installation scenarios:

• Floating production storage and offloading (FPSO) units: For guiding flexible risers connecting subsea infrastructure to the floating vessel.

• Offshore wind farms: To protect dynamic power cables as they enter turbine transition pieces or substations.

• Fixed offshore platforms: For static risers or umbilicals routed from the seabed into platform legs or conductor guides.

• Subsea export and import lines: Where pipelines or cables transition from seabed up through vertical or curved J-tubes mounted on structures.

These installations can be temporary during pull-in operations or left permanently in place for long-term protection.

Philson J-tube centralisers are small yet vital components that significantly enhance the reliability, safety, and performance of offshore riser and cable systems. By ensuring proper alignment, minimizing wear, and reducing installation risks, they play a foundational role in the success of offshore pipeline and power transmission infrastructure.