Cable Guide Tube Centralisers Installation

Installing a cable guide centralizer (also known as a J-tube centraliser clamp) in the offshore wind power industry secures the center position of the submarine cable in the J-tube, preventing damage from friction with the tube wall during installation.

Below are the installation steps and precautions.

Installation steps

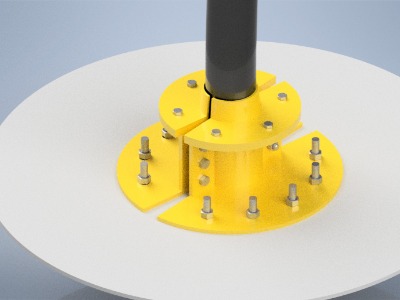

Polyurethane J-tube centralizers typically adopt a Haversian (half-and-half) design. The installation process can be summarized as follows:

1. Preliminary preparation and inspection

• Confirm specifications: Ensure that the centralizer's inner diameter matches the outer diameter of the submarine cable and its outer diameter is compatible with the inner diameter of the J-tube.

• Component inspection: Inspect the two halves of the centralizer for cracks or deformation, ensure the polyurethane gasket is intact, and check all connecting bolts, nuts, and other fasteners.

• Surface cleaning: Thoroughly clean the cable surface where it will be installed from mud, oil, or other debris to ensure a secure installation and prevent damage to the cable.

• Positioning marks: Accurately mark the centralizer installation location on the cable according to the design drawings.

2. Installing the centralizer

• Placing the gasket: First, install the polyurethane gasket into the corresponding groove on the inside of the centralizer clamp. Some designs use a method where the gasket protrusion snaps into the clamp recess for positioning.

• Closing the clamp: Carefully snap the two halves of the centralizer with the gasket together at the marked location on the cable.

• Fastening: Fasten the two halves of the centralizer together using the dedicated locking screws and nuts. Be sure to tighten to the specified torque using a torque wrench or other tool according to the product manual or design requirements to ensure sufficient holding force and prevent loosening due to underwater movement or current impact.

3. Post-installation and inspection

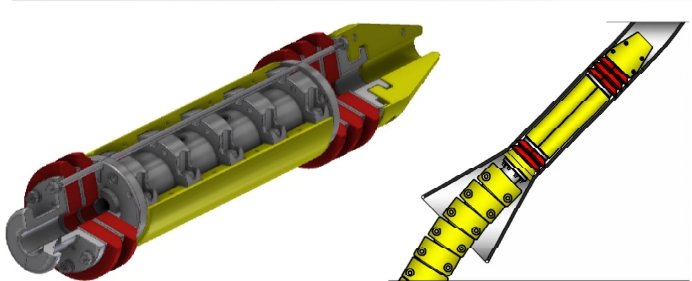

Attaching a bend limiter (if required): A cable bend limiter is sometimes installed at the centralizer outlet to prevent excessive bending of the cable at the J-tube outlet.

Final inspection: Confirm that all fasteners are securely tightened and that the centralizer shows no signs of wobble or misalignment.

Installation precautions

• Avoid using sharp tools: During installation, avoid using sharp metal tools such as screwdrivers and crowbars to pry directly at the centralizer, especially on the polyurethane components, to prevent scratching or damaging the surface.

• Use lubricants with caution: If lubricants are required to aid installation, choose water-based or polyurethane-compatible lubricants. Avoid oil-based or solvent-based lubricants, as they may corrode the polyurethane.

• Follow design requirements: Ensure installation is strictly in accordance with the engineering design drawings and product specifications, including installation location and tightening torque. Do not make any changes at will.

• Underwater operation safety: If installation involves underwater work, it must be performed by a professional team of divers, and appropriate underwater communication, safety, and support measures must be in place.

• Environmental conditions: Offshore installation operations are significantly affected by weather and sea conditions. Closely monitor wave, tide, and wind conditions, and select an appropriate operation window to ensure the safety of personnel and equipment.

Advantages of polyurethane J-tube centralizers

The following advantages are the key factors in choosing polyurethane J-tube centralizers:

• Strong corrosion resistance: Polyurethane material resists seawater corrosion and has a long service life.

• Easy installation: The Haversian design eliminates the need for complex tools, allowing for quick assembly on-site, improving construction efficiency.

• Excellent protection: Its excellent wear resistance and elasticity effectively protect submarine cables from abrasion and impact.

• Lightweight: Polyurethane's low density makes it lightweight in water, adding no additional burden to the cable.

Offshore wind power accessories

Installing polyurethane J-tube centralizers in offshore wind power plants requires meticulous preparation, strict adherence to procedures, and attention to detail. From checking specifications and cleaning the surface to precise positioning and tightening to specifications, every step is crucial to the long-term safety of the cable. If you have further questions about offshore wind power cable protection or would like a quote, please contact us at sale06@kfqizhongji.com.