Submarine Cable Protection in Northern Europe

Polyurethane protective tubing is a cost-effective solution for protecting submarine pipelines and cables from abrasion and impact during installation and operation. It is designed as a protective "sleeve" that can be installed during pipeline or cable laying or unloading. This approach helps minimize the need for additional vessels or equipment, effectively reducing project costs.

Causes and consequences of cable damage in Nordic waters

Submarine cables in Nordic waters face multiple risks. Major sources of damage include commercial fishing and anchoring, while some failures are caused by natural disasters such as submarine currents, storms, submarine landslides, and mudslides.

Even though submarine cables are protected from risk through burial, armoring, and proper route planning, damage cannot be completely avoided. Cable repairs are not uncommon. On average, one submarine cable is damaged every three days worldwide, and approximately 150-200 cable failures occur annually.

When a cable failure occurs, engineers use testing and geolocation methods to locate the damage, sometimes incorporating ais vessel tracking systems to investigate the cause. While damage to a single cable typically doesn't cause significant service disruption, repairs are time-consuming and costly, posing significant challenges to operators and project safety.

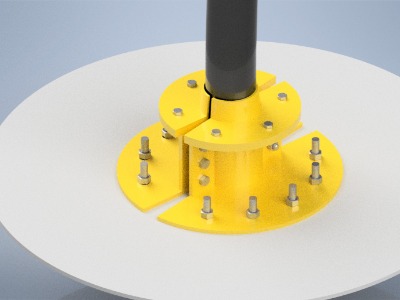

Some nordic countries ordered a batch of polyurethane protective tubes from philson. Each section is 5 meters long, 60 sections, and the thickness is 25mm.

Features of submarine cable and pipeline protection systems

• Excellent abrasion resistance: Effectively resists current flow and abrasion in the subsea environment.

• High elasticity and flexibility: Maintains stable protection under wave and tidal forces.

• Chemical and UV resistance: Withstands long-term erosion in the marine environment.

• Excellent hydrolysis resistance: Ensures long-term protection for over 20 years.

• Thermal stability: Maintains reliable performance even under extreme temperature conditions.

Contact us

Contact us today for a free consultation to learn more about customized solutions for cable and pipeline protection systems in the nordic seas.