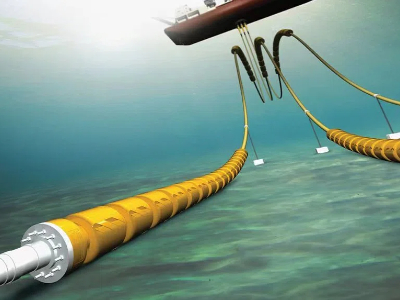

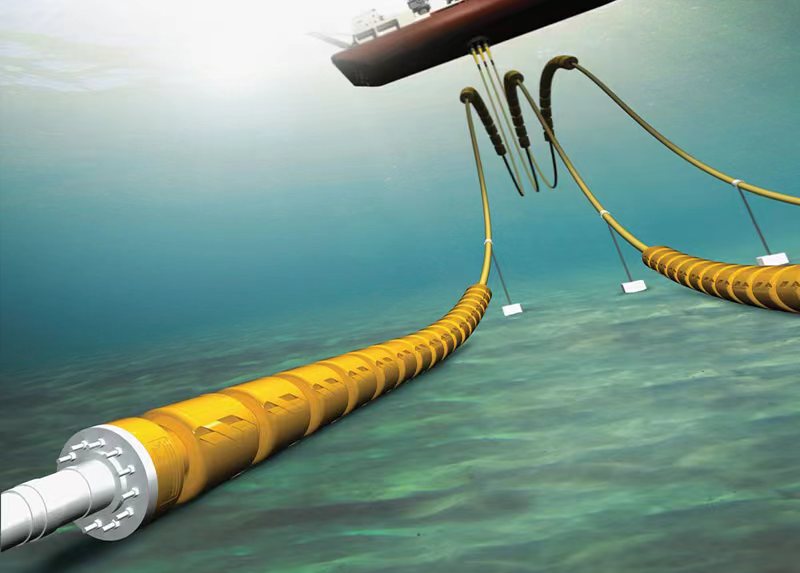

Mold-pouring polyurethane bend restrictors are essential protective devices during the installation of offshore wind power, subsea oil and gas development, and communication cables. Their primary function is to limit the cable's bend radius when it enters rigid structures (such as J-tubes and I-tubes) or interfaces with subsea equipment, preventing mechanical damage or cable failure caused by excessive bending.

Bend restrictors' functions on the subsea

• Prevents excessive cable bending: Restrictors the minimum bend radius to avoid stress concentration.

• Extends cable life: Reduces fatigue damage and improves long-term operational reliability.

• Stabilizes the mounting structure: Provides additional support against external environmental forces such as tidal currents and waves.

• Widely applicable: Used in submarine power cables, fiber optic communication cables, umbilicals, and flexible pipes.

Advantages of cast polyurethane

Bend restrictors are typically made of polyurethane. Polyurethane produced through mold-casting offers the following advantages:

• High abrasion resistance: Withstands friction and impact in seawater environments.

• Excellent seawater corrosion resistance: Maintains stable performance even after prolonged immersion in deep-sea environments.

• High strength and flexibility: Resists breakage under high loads and repeated bending.

• Customizable: Through the mold-casting process, bend limiters can be customized to suit different cable diameters and structures.

• Excellent overall moldability: Reduces splicing, improving structural integrity and sealing.

Pouring process

• Mold design and manufacturing: Design the bend restrictor module mold based on the cable diameter and usage scenario.Modular production can shorten the production cycle and can be used for projects with tight schedules.

• Polyurethane raw material preparation: Select a high-quality polyurethane formula that is resistant to hydrolysis and aging.

• Pouring: Liquid polyurethane is injected into the mold cavity and cured.

• Demolding and post-processing: The cured product is demolded, and the surface is polished, inspected, and treated as necessary.

• Assembly and testing: Multiple modules are assembled into a complete bend limiter, and then tested for mechanical and seawater resistance.

Subsea polyurethane bend limiter

Bend limiters manufactured using the mold-casting polyurethane process not only effectively protect cables and umbilicals in deepwater environments, but also ensure structural reliability and longevity. The flexibility of this process and the excellent performance of polyurethane materials make it one of the most ideal cable protection solutions in the offshore engineering field.