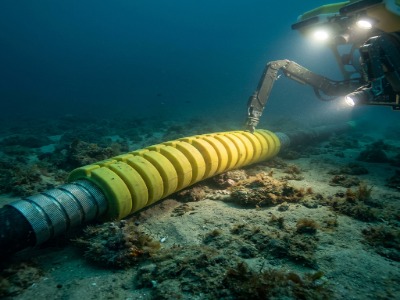

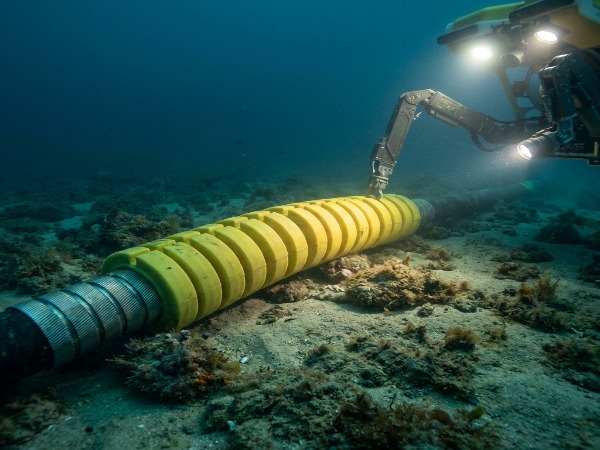

In offshore oil & gas and offshore wind sectors, dynamic cables or umbilicals with a 150mm diameter are critical lifelines for power and signal transmission. For such large-diameter lines, the application of a Bend Restrictor (BSR) is not merely physical shielding—it is a precision-engineered mechanical protection solution.

I. API 17L Compliant Bend Restrictors (BSR) for 150mm Subsea Cable Protection

The core design logic for a 150mm cable BSR relies on Mechanical Interference to achieve effective stress redistribution.

1. Calibration of Locking Bend Radius (LBR)

The primary design parameter is the LBR. According to API 17L (Specification for Flexible Pipe Ancillary Equipment) standards:

Design Rule: $LBR$ must always remain greater than the cable's Minimum Bend Radius (MBR).

Safety Margin: Typically, LBR≈1.1*MBRstorage. For a 150mm cable with a static MBR of 2250mm, the BSR is usually calibrated to an LBR of approximately 2500mm to compensate for manufacturing tolerances and long-term material creep.

2. Contact Pressure and Load Distribution

When the cable is subjected to bending moments (M) from currents or self-weight, the interlocking BSR vertebrae engage. Professional-grade BSRs undergo Finite Element Analysis (FEA) to verify structural integrity under maximum design loads, ensuring no localized stress concentrations cause polyurethane yield.

II. Precision Engineered Mechanical Protection for Offshore Wind & Subsea Umbilicals

Restrictors for 150mm cables endure immense radial pressure, requiring premium material properties:

Hydrolysis Resistance: Utilizing Polyether-based PU to withstand 15+ years of seawater immersion without degradation.

Creep Control: High-grade BSRs must exhibit low-creep characteristics to ensure the locking angle does not drift over time under constant load.

Fastening Systems: Bolts and fasteners are typically made from Super Duplex steel or Monel 400 to eliminate structural failure caused by galvanic corrosion.

III. Technical Challenges in Typical Applications

1. J-Tube Exit Protection

At offshore platforms, 150mm cables exit through J-Tubes. At the exit point, cables are prone to sharp bending due to "Free Span" suspension. The BSR system provides progressive stiffness, converting point loads into curved loads to protect internal copper cores from fatigue.

2. Landfall and Uneven Seabed Zones

In rocky areas or landfall sections, cables move reciprocatingly due to tides. Here, the 150mm BSR serves a dual purpose: as a limit-stop and an Abrasion Shield, with thick PU walls resisting sand and silt erosion.

IV. Technical Specifications (150mm Reference)

Item | Typical Specs |

Compatible Cable Diameter | 150mm±5mm |

Interlocking Angle | 1.5° - 3.5° |

PU Hardness | Shore 85A - 95A |

Design Life | 15+ Years |

Impact Resistance | 15+kJ |

V. Conclusion

The design of a BSR for 150mm subsea cables is a sophisticated integration of polymer science, marine mechanics, and precision engineering. Custom calculations—accounting for submerged weight, maximum tension, and environmental loads (waves/currents)—are essential to ensure the long-term integrity of subsea assets. Simply provide your technical drawings or cable data sheets, and our engineers will provide a detailed quotation for your specific operating conditions. [ Send Inquiry Email ]