Why Choose a Split Sleeve for Offshore Cable Protection

In the demanding world of offshore energy, where subsea power cables, fiber optic lines, and umbilicals are constantly exposed to harsh marine conditions, reliable cable protection is essential. One of the most practical and effective solutions is the split flexible protection sleeve. Designed specifically to safeguard cables from abrasion, impact, and environmental damage, this product offers critical advantages for both installation teams and long-term infrastructure reliability.

•

What is a split flexible protection sleeve?

A split flexible protection sleeve, also known as a subsea protection sleeve or cable protection pipe, is a modular device designed to enclose and shield cables on the seabed. Its split design allows it to be opened and wrapped around existing cables without disconnecting or pulling them through, making it ideal for both new installations and retrofit projects.

Key features

• Polyurethane material

Manufactured from high-performance polyurethane elastomer, the sleeve delivers superior resistance to impact, wear, saltwater corrosion, and temperature fluctuations common in subsea environments.

• Typical lengths

Standard sleeve modules are available in lengths from 500 mm to 2000 mm, allowing flexibility based on the length of the cable section that needs protection.

• Symmetrical structure

The symmetrical design simplifies alignment and allows for rapid offshore installation. This not only improves efficiency but also reduces vessel time and associated costs.

Why use a split sleeve for offshore cable protection?

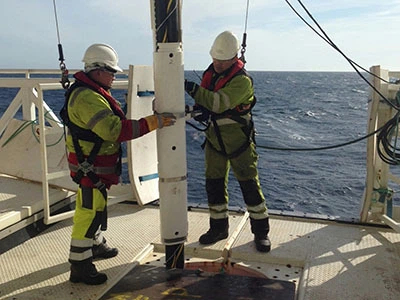

• Fast and easy installation

The split design eliminates the need to thread cables through a full-length pipe. Instead, the sleeve opens and clamps around the cable, significantly reducing installation time, especially in tight working windows offshore.

• Minimal downtime for repairs or retrofits

In the event of cable exposure or damage, split sleeves can be installed as a retrofit solution without disturbing the existing system layout.

• Strong mechanical protection

Polyurethane offers excellent abrasion resistance and impact absorption, making it suitable for high-risk zones such as cable touchdown areas, pipeline crossings, or rocky seabeds.

• Modular and scalable

Multiple sleeves can be connected to form longer protective runs, offering complete flexibility in coverage length.

• Improved operational safety

By protecting critical subsea infrastructure, these sleeves reduce the risk of cable failure, electrical faults, and the need for costly offshore interventions.

Ideal applications

• Offshore wind farms

• Subsea power transmission systems

• Oil and gas umbilicals

• Fiber optic communication lines

• Cable transitions near J-tubes or hang-off points

Whether you're working on offshore wind, oil & gas, or subsea communications, the cable protection pipe provides a rugged, easy-to-install, and cost-effective way to extend the life of your subsea cables. Its polyurethane construction, modular sizing, and symmetrical design make it a standout choice for engineers looking to combine protection and efficiency in offshore operations.