In the offshore wind industry, the cost of a single submarine cable failure can exceed $2 million per incident. This guide provides a deep-dive analysis into the mechanics of protection, helping engineers select between bend stiffeners, restrictors, and integrated CPS solutions.

1. The Mechanics of Protection: How to Protect Offshore Wind Cables?

To protect a cable, we must address three physical enemies: Tension, Bending, and Fatigue.

MBR Management: Every subsea cable has a Manufacturer’s Minimum Bend Radius (MBR). If the cable bends beyond this, the copper/fiber cores can experience "kinking" or insulation cracking.

Vortex-Induced Vibration (VIV): In high-current areas, cables can vibrate, leading to rapid fatigue. A CPS adds the necessary mass and damping to suppress these vibrations.

Abrasion: At the "touch-down point" (where the cable meets the seabed), specialized polyurethane shells prevent the rocks and sand from scouring the cable jacket.

2. Bend Stiffener vs. Bend Restrictor: Deep Technical Comparison

Working Principle: It is a conical-shaped device that provides a gradual increase in stiffness. It acts as a "damper" to prevent sharp bending at the connection point (Hang-off).

Key Parameter: Stiffness Gradient. A high-quality stiffener must have a tailored PU hardness (usually Shore 90A - 95A) to ensure there is no "hard spot" where the cable enters the device.

Primary Scenario: Essential for Floating Offshore Wind (FOW) where the turbine is constantly moving.

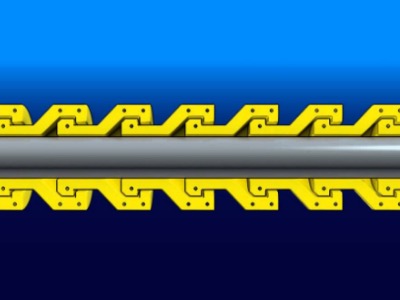

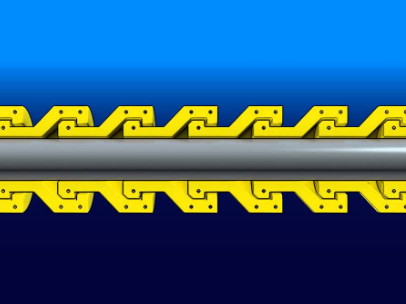

Working Principle: It consists of interlocking "half-shells." They move freely until they reach a pre-set angle, at which point they mechanically lock together.

Engineering Detail: Locking Radius. The lock angle is calculated based on the cable's MBR and a 10% safety margin.

Primary Scenario: Ideal for J-tube exits and static subsea deployments where the cable must be protected from over-bending during the lay process.

3. Market Insights: Submarine Cable Bend Restrictor Market

The market is shifting from "one-size-fits-all" to Bespoke Solutions.

Material Innovation: The trend is moving toward Hydrolysis-resistant Polyurethane, which doesn't degrade even after 25 years in salt water.

Diverless Installation: With offshore labor costs rising, the demand for "Snap-on" or "Bolt-less" bend limiters is skyrocketing.

Dynamic Connectors: As wind farms move to deeper waters (Floating Wind), the dynamic bend stiffener connector segment is the fastest-growing niche.

4. Key Components of an Effective CPS

A high-performance cable protection system for offshore wind usually consists of:

Articulation Links: The "backbone" that limits the bending angle.

J-tube Seals & Centralizers: Ensuring a secure and debris-free entry into the turbine foundation.

Strain Relief Units: Managing the tension at the hang-off point.

Summary

Protecting subsea cables requires a balance of high-strength materials (like specialized Polyurethane) and precise engineering. Whether you are deploying cable protection systems for offshore wind or analyzing the bend stiffener vs. bend restrictor dilemma, the goal remains the same: ensuring a 25-year operational life in the harshest environments on earth.