In the field of deep-sea engineering, riser systems hanging from floating platforms or dynamic cables winding from the seabed to surface facilities are constantly subjected to tremendous environmental loads. Effectively managing the self-weight and tension of these long, flexible structures to ensure their safety and longevity poses a core challenge for engineers. Distributed Buoyancy Technology is precisely the key to addressing this challenge.

What is Distributed Buoyancy Modules?

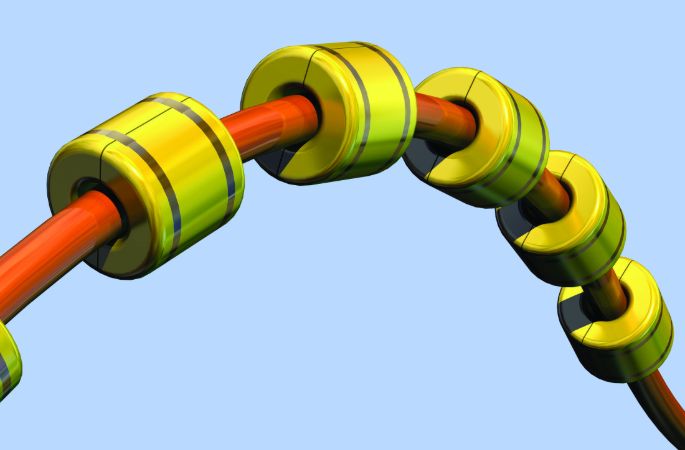

Distributed Buoyancy Modules, as the name implies, does not involve providing a single, massive buoyancy block. Instead, it involves installing numerous independent buoyancy modules at specific intervals and configurations along a pipeline, riser, or cable, much like a "necklace." This design aims to shape the overall configuration of the catenary system by providing uniform, controllable net buoyancy, thereby optimizing its mechanical performance.

Its core value lies in a simple physical principle:

By utilizing the uplift force provided by the distributed buoyancy modules to offset part or all of the pipeline's submerged weight, the tension at the top of the system is significantly reduced, and its bending curvature at the touch-down point on the seabed and in wave-affected zones is controlled.

Why is Distributed Buoyancy Needed?

Deep-sea risers or dynamic cables without distributed buoyancy modules can generate extremely high hanging tensions at the top due to their significant self-weight and may fail at the touch-down point due to excessive bending. Distributed buoyancy is primarily introduced to solve the following four key problems:

1. Reduce Top Tension

The full weight of the pipeline is borne by the platform or floating structure. By using buoyancy modules to "lift" part of the pipeline weight, the top tension can be greatly reduced, enabling the system to be used with lighter platforms or in deeper waters.

2. Control Touch-Down Point Bending

For Steel Catenary Risers, a bending area known as the touch-down point forms where it contacts the seabed. Excessive bending stress can lead to pipeline fatigue or even fracture. Distributed buoyancy can elevate this area, creating a smooth "buoyant span" that keeps the bending curvature within safe limits.

3. Form Optimized Configurations

By carefully designing the distribution of buoyancy modules, engineers can precisely "sculpt" the pipeline's shape to better adapt to specific sea conditions and platform motions.

4. Avoid Vortex-Induced Vibration

Subsea pipelines can experience Vortex-Induced Vibration in ocean currents, leading to metal fatigue over time. Specific distributions of buoyancy modules can alter the pipeline's natural frequency, helping it avoid the dominant vortex shedding frequencies, thereby extending its fatigue life.

Typical Application Scenarios for Distributed Buoyancy

1. Steel Catenary Risers

In deepwater oil and gas development, SCRs extend directly from the platform to the seabed. Their immense self-weight makes bending stress at the touch-down point a critical design bottleneck. Installing a section of **buoyancy sleeves** upstream of the touch-down zone effectively lifts the pipeline, creating a gentler bend. This is one of the most classic applications of distributed buoyancy.

2. Dynamic Cables

In floating offshore wind farm projects, dynamic cables connecting the floating platform to the static seabed cable are crucial components. To prevent excessive bending and fatigue at the seabed contact point and the platform hang-off point, distributed buoyancy modules are typically installed along the mid-section of the cable, forming a "wave-shaped" or "lazy-S" configuration to absorb the platform's dynamic movements.

3. Umbilicals and Flexible Risers

These lifelines for transmitting power, hydraulics, and chemicals also require meticulous configuration management. Distributed buoyancy ensures they maintain safe bending radii and reduce the effective tension on the platform within the complex and variable marine environment.

4. Subsea Pipeline Spanning

When a pipeline needs to cross rugged seabed terrain or existing pipelines, distributed buoyancy can "bridge" it, creating a safe suspended span that avoids direct contact and abrasion with the seabed or other structures.

Conclusion

Distributed buoyancy has evolved from a supplementary technology into an indispensable core element in the design of deepwater riser and dynamic cable systems. It embodies the wisdom of "using softness to overcome hardness" in deep-sea engineering—skillfully harnessing buoyancy to tame immense environmental forces.

As a leading domestic provider of deepwater buoyancy solutions, we understand the unique challenges faced by each marine engineering project. We offer a full range of high-performance distributed buoyancy modules, covering applications from shallow water to depths exceeding 3000 meters. Our engineering team provides end-to-end services, from initial concept design and hydrodynamic analysis to customized product delivery and installation support, ensuring your riser, dynamic cable, and subsea pipeline systems operate safely in their optimal configuration.

Contact our expert team now for free technical consultation and project proposals!