Roller Coaster PU Wheel Upgrade Success Case

On a roller coaster, wheel assemblies serve as the contact point between passenger-carrying cars and track rails. Each assembly usually has a minimum of 3 wheels, though some may include more.

The wheels are typically arranged in three types:

Running wheels (alternatively called road wheels or tractor wheels): Located on top of the rails, they support the entire weight of the roller coaster train.

Side friction wheels: Mounted on a horizontal plane, either inside or outside the rails. These wheels press against the rail sides to keep the train aligned centrally.

Up-stop wheels (also referred to as underfriction wheels or up-lift wheels): Positioned beneath the rails, they prevent the train from lifting off the track.

I. Case Background: Core Demands of an Established Amusement Park

A large-scale amusement park with 15 years of operation owns 3 main roller coaster routes. Among them, the "Speed Whirlwind" wooden roller coaster has encountered a series of problems due to prolonged operation: the original steel wheels generate a noise peak of 85 decibels, seriously affecting the park's acoustic environment; the frictional wear between the track and wheels has intensified, requiring an investment of 3,000 USD per month for component maintenance and replacement; meanwhile, passengers have reported obvious vibrations during operation, with experience satisfaction dropping by 32% compared to the initial opening period.

To address the above issues, the amusement park contacted Philson, a professional wheel manufacturer, and put forward three core demands: first, reduce operating noise and vibration to enhance passenger experience; second, extend wheel service life to lower operation and maintenance costs; third, ensure material strength meets the high-strength operation standards of roller coasters to guarantee operational safety.

II. Problem Diagnosis: Analyzing Root Causes from Material Properties

Philson's technical team conducted a comprehensive inspection of the amusement park's existing steel wheels and operating environment. Combining the working characteristics of roller coaster wheels (direct contact with the track, bearing the entire vehicle load, high-frequency start-stop and steering), they identified that the root cause of the problems lies in the mismatch between material selection and scenario requirements:

Wear and Noise Issues: Although steel wheels have the advantage of high strength, they have a high friction coefficient (0.35). Hard contact with the track easily generates metal friction noise, and the rigid material lacks buffering, leading to obvious vibration transmission;

Operation and Maintenance Cost Issues: The hard friction between steel wheels and the track accelerates the wear rate of both, with the average service life of wheels being only 3 months, far below the industry average;

Experience Shortcomings: The rigid material cannot absorb the impact force during operation, and vibrations at track joints are directly transmitted to the carriage, affecting riding comfort.

III. Solution: Precise Adaptation of Polyurethane Materials

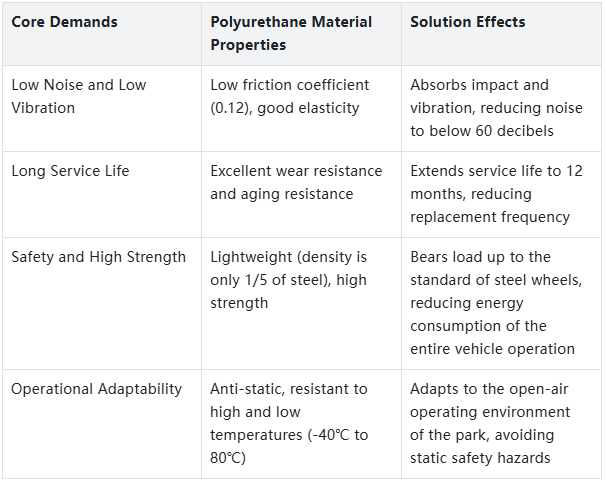

Based on the diagnosis results, Philson's technical team, leveraging its own material R&D advantages, customized a polyurethane (PU) roller coaster wheel upgrade solution for the amusement park. The core logic revolves around the precise matching between the core properties of polyurethane materials and scenario requirements:

1. Material Selection: Empowerment by Polyurethane Properties

To meet the working requirements of roller coaster wheels, Philson selected high-polymerization polyurethane materials, whose key properties perfectly align with the demands:

2. Product Customization: Detail Optimization to Enhance Adaptability

In addition to the core materials, Philson customized and optimized the wheel structure based on the track curvature and load parameters of the "Speed Whirlwind" roller coaster: an arc-shaped contact surface design was adopted to increase the fit with the track; the wheel core was made of high-strength aluminum alloy to further reduce the overall weight; a wear-resistant protective ring was added at the edge to avoid local wear at track joints.

3. Supporting Services: Full-Process Guarantee for Implementation

To ensure the smooth implementation of the upgrade solution, Philson provides a full-process service of "inspection-customization-installation-after-sales": technical personnel are arranged to guide on-site wheel replacement and conduct synchronous track cleaning and maintenance; a monthly inspection mechanism is established to monitor the wheel operation status in real-time; 24-hour emergency replacement service is provided to ensure the continuity of the amusement park's operation.

IV. Case Results: Dual Improvement in Safety and Benefits

After the amusement park adopted Philson's polyurethane wheels, a 6-month operation monitoring showed that all indicators achieved significant optimization:

Experience Improvement: Operating noise decreased from 85 decibels to 58 decibels, passenger satisfaction with vibration feedback increased by 47%, and the passenger flow of the "Speed Whirlwind" route increased by 18% month-on-month;

Cost Optimization: The frequency of wheel replacement decreased from once a month to once every 12 months, operation and maintenance costs decreased by 72% year-on-year, and maintenance costs were saved by approximately 11,000 USD within a year;

Safety Guarantee: No wheel failures were recorded during the 6-month operation period, and the material strength test met the highest standard of "Safety Specifications for Amusement Rides" (GB 8408-2018);

Energy Consumption Reduction: The lightweight wheels reduced the energy consumption of the roller coaster's traction system by 12%, saving approximately 22,000 USD in electricity costs annually.

V. Case Summary: Core Logic of Material Selection

This case, through the upgrade of steel wheels to polyurethane wheels, confirms the core principle of roller coaster wheel material selection—not pursuing high strength unilaterally, but achieving precise matching between material properties and operating scenarios. With the composite advantages of "lightweight and high strength, low friction and high elasticity", polyurethane materials perfectly solve the noise, wear and experience pain points of the established roller coaster.

As a professional wheel manufacturer, Philson can not only provide polyurethane wheels but also customize multi-material solutions such as nylon wheels, rubber wheels and steel wheels according to the operating needs of different amusement facilities. It also provides efficient wheel replacement and operation and maintenance services. If you have needs for amusement facility wheel upgrade or customization, please feel free to contact Philson's technical team!