AGV Polyurethane Wheels Performance Types

As the feet of Automated Guided Vehicles (AGVs), the performance of AGV wheels directly determines the operational efficiency, safety, and service life of the entire AGV system. Among various wheel materials and types, AGV polyurethane wheels have become a core component in the field of automated material handling due to their outstanding comprehensive performance. This type of wheel is made from high-molecular-weight polyurethane elastomer, which not only provides excellent traction, ensuring stable travel on complex working surfaces such as concrete, asphalt, and warehouse plastic floors, but also integrates wear resistance, impact resistance, and strong load capacity. This effectively addresses the pain points of traditional rubber wheels being prone to aging and metal wheels having poor shock absorption in industrial scenarios. This article will conduct an in-depth analysis of AGV polyurethane wheels from four core dimensions—structural configuration, stability mechanism, and load-bearing performance, —to reveal their technical characteristics and application value.

Structural Configuration of AGV Polyurethane Wheels: Classification and Synergistic Mechanism

The wheel system of an AGV is a highly synergistic mechanical assembly. The reasonable combination of wheels with different configurations is a prerequisite for achieving precise and stable operation. Classified by function, the configuration of AGV polyurethane wheels is mainly divided into three categories: drive wheels, guide wheels, and load wheels. Each type has a clear functional positioning and forms a synergistic operating system with the AGV's drive module, navigation module, and body structure.

1.1 Drive Wheel: Core Power Output Component

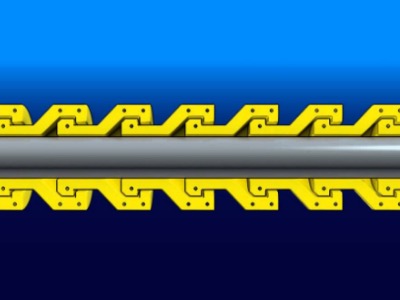

The drive wheel is the core power source of the AGV, responsible for converting electrical energy from the motor into mechanical energy to drive the vehicle for actions such as forward, reverse, and steering. AGV polyurethane drive wheels typically adopt an integrated structure of "polyurethane tread + metal hub + bearing" and are directly connected to the reducer and servo motor to form the drive unit. The hardness of the polyurethane tread on drive wheels is designed according to the application scenario (Shore A 70-95): for heavy-duty AGVs (load capacity ≥ 5 tons), high-hardness polyurethane (Shore A 90-95) is used to enhance load capacity; for light-load AGVs in scenarios like electronics workshops, medium-soft polyurethane (Shore A 70-80) is used to improve ground adaptability. Additionally, the drive wheel surface often features grooved or herringbone patterns, which can increase the friction coefficient between the wheel and the ground, preventing slippage during heavy-load start-stop or braking.

1.2 Guide Wheel: Guarantee for Precision Navigation

The guide wheel, also known as the steering wheel or positioning wheel, is responsible for ensuring the AGV follows the preset path and maintaining the accuracy of the navigation trajectory. AGV polyurethane guide wheels are usually installed at the front or middle of the vehicle body and adopt a swivel rotation structure, allowing them to adjust direction in real-time according to navigation sensor signals. The polyurethane material of the guide wheel possesses good elasticity, effectively absorbing lateral impact forces generated during AGV steering adjustments and avoiding path deviation caused by rigid collisions.

1.3 Load Wheel: Foundation for Load-Bearing and Stability

The load wheel, also called the carrier wheel, is mainly used to support the weight of the AGV body and cargo, balance the vehicle's center of gravity, and prevent tipping during operation. AGV polyurethane load wheels are typically installed symmetrically on both sides of the vehicle body, with the quantity configured from 4 to 8 based on load requirements. The polyurethane tread of load wheels has low rolling resistance, which can reduce energy consumption during AGV travel, while also avoiding scratches on clean room floors (e.g., in pharmaceutical workshops, semiconductor factories).

Stability and Load-Bearing Performance of AGV Polyurethane Wheels: Influencing Factors and Optimization Strategies

Stability and load capacity are two core performance indicators of AGV polyurethane wheels, directly related to AGV operational safety and cargo transport reliability. The comprehensive performance of the wheels is influenced by multiple factors such as structural parameters, material properties, design details, and system matching. The key influencing factors and corresponding optimization measures are analyzed in detail below.

2.1 Structural Parameters: Performance Foundation

The wheel's diameter, width, and hub structure are fundamental factors determining stability and load capacity. From a mechanical perspective, wheels with larger diameters have smaller rolling resistance coefficients, reducing vibrations caused by ground unevenness (such as small gaps or protruding particles) and improving travel stability. Taking logistics warehouse AGVs as an example, the drive wheel diameter for ordinary cargo AGVs is 150-200mm, while AGVs used in outdoor container yards employ large-diameter wheels (300-400mm) to adapt to uneven concrete ground. Wheel width is positively correlated with load capacity: under the same material and diameter conditions, a wheel with an 80mm width can increase load capacity by 30% compared to a 50mm wide wheel, because a wider contact area disperses ground pressure. Furthermore, hubs made of high-strength aluminum alloy or steel can enhance the structural rigidity of the wheel, prevent hub deformation under heavy loads, and ensure coaxiality between the wheel and the motor.

2.2 Material Properties: Performance Core

The polyurethane material used in AGV wheels is the key factor for their excellent performance, showing significant differences from traditional rubber and plastic materials. Polyurethane is a high molecular material formed by the reaction of isocyanate and polyol, whose mechanical properties can be precisely adjusted by modifying the raw material ratio. In terms of stability, polyurethane material has a high friction coefficient (0.6-0.8), 20%-30% higher than natural rubber, ensuring sufficient traction between the wheel and the ground, preventing slippage even on wet or oily surfaces. Regarding wear resistance, the wear rate of polyurethane is only 1/5 that of rubber. In industrial scenarios, the service life of polyurethane wheels can reach 8000-12,000 hours, while rubber wheels only last 2000-3000 hours. In terms of load capacity, high-performance polyurethane has a compressive strength of 30-50 MPa, enabling it to withstand long-term heavy load pressure without permanent deformation.

2.3 Design Details: Key to Performance Enhancement

Wheel design details significantly impact stability and load-bearing performance. Tread patterns need to be designed according to the application scenario: smooth patterns are suitable for clean rooms with flat floors, avoiding dust accumulation; grooved patterns are suitable for logistics warehouses with more floor debris, preventing debris from jamming between the wheel and the ground; herringbone patterns are suitable for outdoor AGVs, enhancing grip on uneven ground. Wheel track (distance between left and right wheels) affects the lateral stability of the AGV: a larger track results in higher lateral stability, which is why heavy-duty AGVs typically adopt a wide-body design to increase the wheel track. The connection between the polyurethane tread and the metal hub uses a "bonding + mechanical locking" structure. The bonding layer uses special adhesive to ensure tight adhesion between the tread and the hub, and mechanical locking (such as grooves on the hub) can prevent relative sliding between the tread and the hub under high-speed rotation or heavy-load conditions.

2.4 System Matching: Guarantee for Performance Realization

The stability and load-bearing performance of AGV polyurethane wheels depend on the matching with the entire AGV system, especially the wheel layout and suspension system. The wheel layout needs to adopt forms such as "2 drive wheels + 4 load wheels" or "4 drive wheels + 4 load wheels" based on load requirements: the 2-drive layout is suitable for light-load AGVs requiring flexible movement; the 4-drive layout is suitable for heavy-duty AGVs, enabling even force distribution among wheels and improving load capacity. The suspension system is divided into rigid suspension and elastic suspension: rigid suspension is suitable for flat floors, ensuring positioning accuracy; elastic suspension uses shock absorbers made of polyurethane to absorb vibrations caused by ground unevenness, maintaining the stability of the vehicle body and cargo, while reducing the impact of vibration on the wheel structure and extending the wheel's service life.

Conclusion and Outlook

As a core component of AGVs, polyurethane wheels have become an important support for the development of automated material handling technology, thanks to their reasonable structural configuration, excellent stability and load-bearing performance, and wide adaptability. With the continuous advancement of technologies such as 5G, artificial intelligence, and big data, AGVs are evolving towards higher precision, larger loads, and more complex environments, which will place higher demands on the performance of polyurethane wheels.