High-performance stacker travelling wheel blocks with 112–500mm diameters and 2.75–40 ton load capacity. Available in polyurethane, cast iron, or steel, ideal for automated stacking systems requiring durability, precision, and smooth motion.

This article introduces the high-performance stacker travelling wheel block, with specifications, material options, and assembly structure, suitable for a wide range of stacker models.

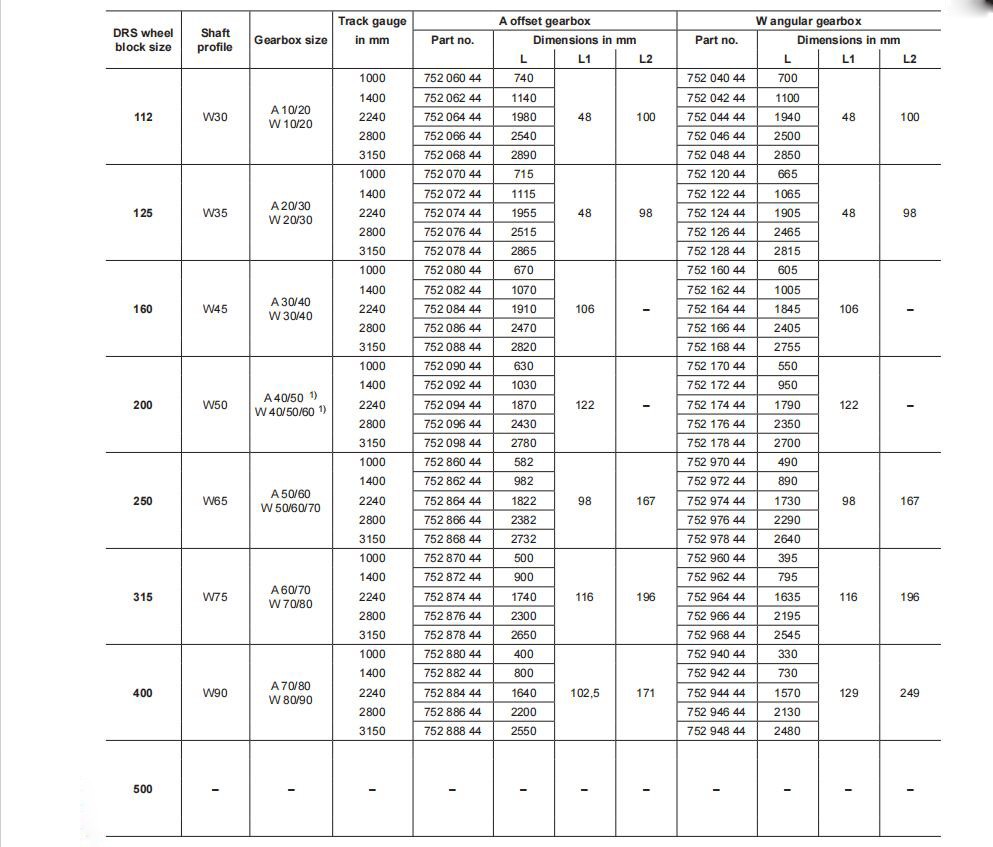

Technical specifications

Wheel diameter: 112mm to 500mm

Load capacity per Demag wheel: 2.75t to 40t

Application: Automated stackers, high-bay warehouse systems, vertical lift modules

The stacker drive wheel set is designed to ensure stable and reliable motion even under continuous operation in demanding industrial environments.

Wheel block system model options

Our stacker wheel block system is available in various model configurations to suit different equipment types and installation positions:

Single flange / double flange / flangeless guide wheels

Top-mounting, side-mounting, or end-plate connected wheel blocks

Driven and non-driven wheel variants are available for pairing use

These flexible models make integration with existing stacker systems simple and efficient.

DRS drive wheel set materials

The stacker drive wheel set material can be customized based on the operating conditions:

Polyurethane-coated wheels: Suitable for silent operation, anti-slip, and wear resistance, especially in clean environments like electronics or pharmaceuticals.

Cast iron or forged steel wheels: Ideal for high-load applications with rougher surfaces, offering maximum strength and longevity.

Nylon or composite material wheels: Optional for lighter-duty stackers or specialized usage.

Each material type is carefully selected to meet your application's durability, traction, and environmental needs.

Stacker wheel block assembly

The complete stacker roller block assembly includes the following components:

Precision-machined wheel core

Bearing seat and sealed bearing units

Shaft sleeve or drive shaft coupling (for powered wheels)

Optional damping layer for shock absorption

Integrated mounting brackets and bolt holes

This modular design enables quick maintenance, easy replacement, and high consistency in multi-unit operations.

Application advantages

High load-bearing capacity per wheel block

Smooth and vibration-free operation

Durable materials for long service life

Flexible mounting options for new or retrofit installations

Ideal for both drive and non-drive wheel positions

Whether your stacker system requires robust drive wheels for heavy loads or low-noise guide wheels for precision movement, our high-performance travelling wheel blocks offer reliable solutions tailored to your requirements. Available in a range of sizes, materials, and installation types, we help ensure your material handling system operates at peak performance.