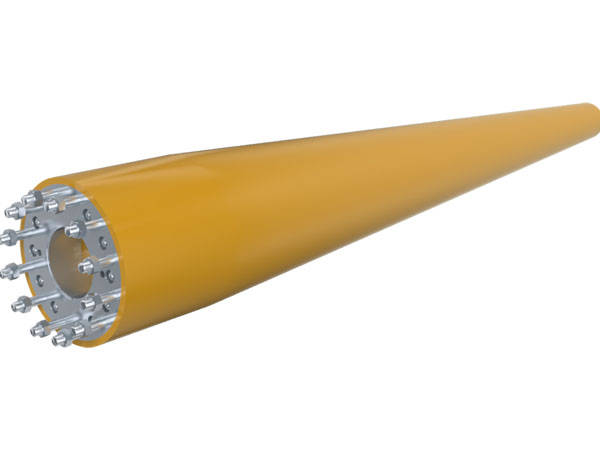

Offshore Cable Bend Strain Relief Protection System

The Bending Strain Relief (BSR) is a high-performance composite component specifically designed for cable protection and service life extension. With its innovative structure and flexible adaptability, it has become the preferred protection solution for industrial cable systems.

Its core structure is composed of polyurethane material and helical steel rods. The synergistic effect of these two materials endows the product with graded stiffness characteristics. It can not only accurately limit the cable bend radius to avoid internal structural damage caused by excessive bending but also provide stable buffer protection for the cable to cope with external impact under complex working conditions. Adopting a symmetrical design, the product breaks directional limitations and achieves consistent omnidirectional performance. Regardless of the cable installation angle, it can exert uniform protection effects, adapting to diverse installation scenarios.

In terms of adaptability, the product offers strong compatibility. When used as a standalone component, it can perfectly fit various cables and hoses with diameters ranging from 19 mm (0.75 in) to 127 mm (5.0 in), covering most commonly used cable specifications in the industrial field. Meanwhile, it can seamlessly match relevant termination product series. No additional adaptive accessories are required, allowing easy integration into existing cable connection systems and reducing upgrade and replacement costs.

Installation convenience is one of its prominent features. It adopts a slip-on design that eliminates the need for complex cable preparation work, such as stripping and welding. The complete installation can be completed in just a few minutes with simple operations, greatly improving construction efficiency and reducing downtime for maintenance. It offers flexible fixing methods, supporting both internally threaded sleeve coupling and flange mounting ring fixation. Users can freely choose according to the actual installation environment and stress requirements to ensure stable and reliable installation without loosening.

In terms of performance advantages, the BSR demonstrates significant practical value. Its unique stress distribution design can evenly distribute the cable's maximum bending point along the length of the cable inside the BSR as load conditions change. This avoids local wear or breakage caused by stress concentration, effectively extending the cable's service life. More notably, the product supports customized adjustments. By optimizing design parameters, it can accurately match the stiffness requirements of different cable systems. Whether for mobile cables requiring high flexibility or fixed cables demanding high stability, it can provide targeted protection solutions, adapting to cable protection needs in various fields such as industrial production, energy transmission, and construction machinery.