Application of Polyurethane Marine Protective Tube in Offshore Oil and Gas

Polyurethane marine protective tube is a high-performance protection solution for offshore oil and gas pipelines, cables, etc. With its excellent polyurethane material properties and interlocking structure design, it plays an irreplaceable role in offshore oil and gas projects.

• The role of polyurethane marine protective tube

In offshore oil and gas platforms, submarine pipelines and cable systems, polyurethane protective tubes are mainly used in the following aspects:

Protect submarine cables and pipelines

Prevent cables or pipelines from being damaged by external impact, friction, drag, vibration or sea currents, and extend the service life of equipment.

Prevent wear and corrosion

In the environment of high salt, high pressure and long-term scouring in seawater, it effectively prevents the surface of cables and pipelines from being corroded, scratched or worn.

Buffer stress and absorb shock

Reduce the transmission of mechanical stress caused by tides, waves, sea currents, etc., and avoid pipelines or cables from breaking due to excessive local stress.

Improve installation convenience

The polyurethane protective tube has a light and flexible structure, which is easy to cut, install and fix on site, simplifying the construction process of marine engineering.

Identification and safety tips

Through multiple color customization, polyurethane protective tubes can also achieve color management of different functional areas to improve overall safety.

• Features of polyurethane protective tubes

As a polymer engineering material, polyurethane has unique properties that give it significant advantages in marine engineering protection, including:

Excellent wear resistance

Polyurethane materials have a stable molecular chain structure and are far more wear-resistant than traditional rubber and plastic materials, making them suitable for long-term exposure to marine environments.

Salt spray and corrosion resistance

Can resist the erosion of seawater, high salt and humidity, ultraviolet radiation and chemical media, ensuring long-term protection effect without attenuation.

High elasticity and impact resistance

Can maintain good deformation recovery ability under external forces such as impact and extrusion to prevent damage to pipelines and cables due to sudden impact.

Good flexibility and tensile strength

Polyurethane protective tubes have good bending properties and are suitable for complex installation environments, such as bending, winding or small space layout.

Resistant to low temperatures and aging

Adapts to extreme marine environments (such as extremely cold waters), is not easy to crack or age, and ensures long-term use.

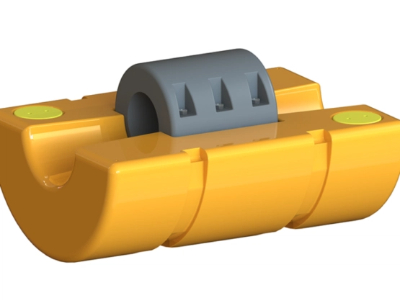

Strong customization capability

Different colors, sizes, and structural forms (such as split type, integral type, spiral winding type) can be customized according to customer needs to adapt to different tube diameters and usage scenarios.

• Application scenarios

Polyurethane marine protection tubes are widely used in the following offshore oil and gas projects:

Offshore platform cable protection

Protect power cables and communication optical cables to prevent damage from external forces or erosion by marine organisms.

Submarine pipeline protection

Cover the oil and gas transmission pipeline to prevent friction between the pipeline and hard objects such as the seabed and reefs, reducing the risk of corrosion.

Riser protection

Buffer the impact of waves and currents on the riser and reduce metal fatigue damage.

Flexible tube and cable fixing and support

Used with J-tube and central tube support systems, multi-point protection and guidance positioning are achieved.

Philson polyurethane marine protection tube has become an indispensable protective tool in offshore oil and gas projects with its excellent performance and reliability. We are committed to providing stronger support for oil and gas transmission systems in more complex marine environments to ensure the safe and efficient development of marine resources. If you have any questions or needs, please contact us at any time.