RGV Wheel Block Maintenance & Replacement

RGV wheel block maintenance is a crucial measure to ensure efficient equipment operation and extend service life. To address common fault scenarios, we provide a detailed set of maintenance and repair methods to help you systematically manage equipment health.

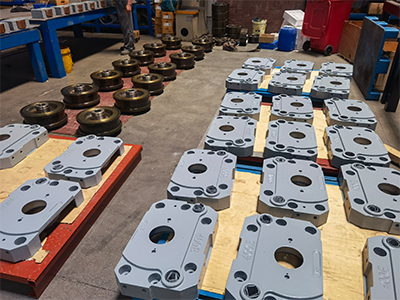

RGV Wheel Block Inspection and Replacement

Comprehensive Inspection Steps: First, cut off the equipment power and perform a systematic inspection of the wheel block. After disassembling the wheel block using professional tools, carefully check the tires for surface wear, cracks, or deformation, and assess the condition of the bearings and seals.

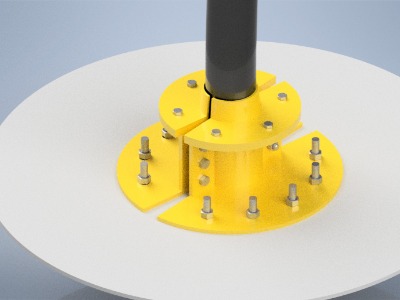

Professional Replacement Standards: For severely worn or damaged tires, new tires made of polyurethane or other wear-resistant materials that meet original specifications should be selected. During installation, pay special attention to the concentricity of the tire and the shaft. Use a torque wrench to tighten the bolts according to the specified torque, ensuring balanced and reliable installation.

RGV Wheel Base and Alignment Adjustment

Precision Measurement: Use high-precision measuring tools to check the distances between wheel blocks, including the span and diagonal dimensions, ensuring all deviations are within the allowable range.

Fine Adjustment Process: If deviations are found to exceed standards, fine-tuning can be performed by adjusting the shims or fasteners of the bearing housing. If necessary, reposition the wheel blocks to ensure all tires are properly aligned, thereby reducing vibration and deviation during operation.

Track System Cleaning and Calibration

Systematic Cleaning Maintenance: Regularly remove foreign objects and accumulated dust from the tracks. Use professional tools to repair deformed or worn sections of the track, ensuring the track surface is smooth and unobstructed.

Precise Track Calibration: Use laser alignment equipment to recalibrate the wheel-rail system, ensuring the track's straightness and flatness meet standard requirements, fundamentally reducing unnecessary tire wear.

Lubrication System Maintenance Standards

Scientific Lubricant Selection: Select the appropriate lubricating oil or grease based on the actual material of the wheel block and the working environment. Strictly avoid using chemicals that could corrode the wheel block material.

Regular Lubrication Schedule: Develop a scientific lubrication schedule. Regularly lubricate the wheel block bearings and track contact surfaces to effectively reduce the coefficient of friction, minimize wear, and extend equipment service life.

Condition Monitoring and Preventive Maintenance

Intelligent Sensor Monitoring: Install wear monitoring or foreign object detection sensors at key locations on the wheel blocks and tracks to monitor the operating status in real time and enable predictive maintenance.

Systematic Regular Inspection: Establish a comprehensive regular maintenance inspection system, including tire wear assessment, track condition inspection, wheel base adjustment, and other items. Preventive maintenance is the most effective means to avoid unexpected failures.

By implementing the above maintenance methods, common problems with straight rail shuttle car tires can be effectively solved, ensuring stable equipment operation, improving operational efficiency, and reducing comprehensive maintenance costs.

If you have requirements for wheel block procurement or replacement, please feel free to contact Philson. We look forward to your inquiry and will provide you with professional product solutions and comprehensive technical support. Contact us!