High-Performance Polyurethane Roller Coaster Friction Wheels

Rollercoaster wheels, commonly found in amusement and theme parks, deliver thrilling experiences while maintaining an exceptional safety record, making them a favorite attraction for young visitors worldwide.

1. Core Structure and Movement

The ride's structure is defined by three primary movements: climbing, sliding, and reversing (though children's coasters typically omit the reversal). The track design varies: it may form a complete loop or be configured for a forward-and-backward shuttle motion.

2. The Science Behind the Thrill

The roller coaster is a vivid demonstration of applied physics. Its movement ingeniously utilizes fundamental physical principles to create a dynamic and controlled experience.

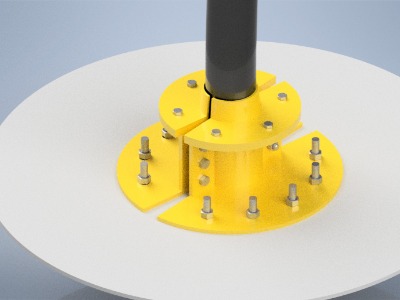

3. The Driving Force: Friction Wheels

Propulsion is primarily handled by friction wheels. Dozens of rotating wheels, arranged in two parallel rows along the track, grip the sides of the train—either at the bottom or top—to push it forward and propel it up steep inclines. This system is often employed:

On climbing turns where a traditional chain cannot operate laterally.

To adjust the train's speed before engaging with the chain lift, ensuring synchronization.

4. The Material Advantage: Polyurethane-Coated Wheels

Polyurethane (PU) coated wheels are the industry standard for roller coaster friction wheels due to their superior material properties. Manufactured via a casting process using liquid polyurethane rubber, they offer significant advantages over conventional rubber wheels:

Exceptional Mechanical Strength: 2-3 times stronger than standard rubber.

Superior Wear Resistance: 5-10 times more durable than natural rubber.

Outstanding Compression Resistance: Maintains integrity under heavy loads.

Wide Hardness Range: Retains high elasticity even at high hardness levels, a unique combination.

High Surface Smoothness & Excellent Machinability: Ensures precise performance and low friction.

Strong Metal Adhesion: Bonds more effectively with metal components than ordinary rubber.

These wheels can be fully customized to meet specific ride requirements, ensuring optimal performance and reliability. For detailed technical specifications and application support, reach out to our engineering team. Contact us!